| 1° THE CONTEXT

The request was specific: How to successfully inject latex (of density 1200kg / m3 and of a viscosity of 15cP) into a large diameter tank (2000 mm) without degrading the quality of the latex produced (surface eddies or injections of air in the fluid would make it porous) |

2° THE CHALLENGE

Manufacturing a valve, integrating a specially designed disc & seat, obtaining a continuous input of fluid in the tank while avoiding the insertion of air bubbles in the Latex. |

|

Darwing profiled disc |

3° THE SOLUTION

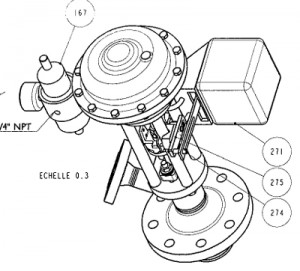

A spray valve, type 603, with a profiled plug, pneumatically actuated and equipped with an electronic positioner 4-20mA. The profile of the plug will result in a “mushroom” shape, i.e. uniform flow and an increased deposition surface, without the formation of large eddies in the tank. The positioner adjusts the opening of the valve in order to obtain the desired flow rate and the necessary fluid pressure. |

|

Spraying Valve type 603 |